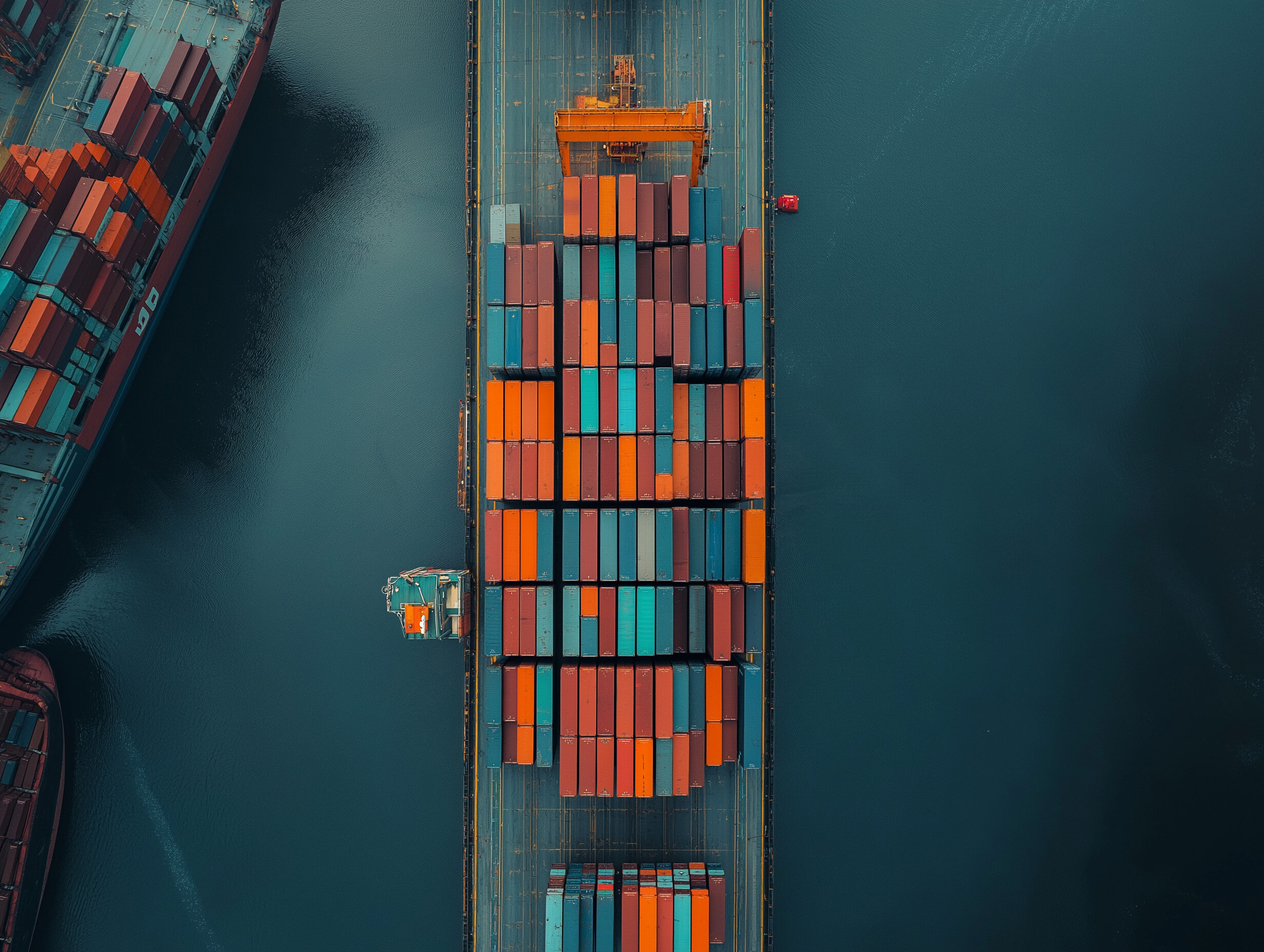

International transport poses challenges due to the risk of damage caused by moisture. This issue can lead to significant financial losses and affect the quality of delivered products. The AbsorTest™ system offers a solution, enabling effective moisture monitoring during transport.

With the advanced AbsorTest™ system, you can fully monitor conditions inside the container during road, rail, sea, and air transport. This state-of-the-art solution allows real-time tracking of key parameters, ensuring cargo safety and helping to minimize the risk of damage.

AbsorTest™ – A Tool for Validating Moisture Protection Efficiency

AbsorTest™ is a comprehensive process that enables field testing to verify the effectiveness of desiccants. The process includes:

- Real-time monitoring with the AbsorTrack™ device.

- Detailed final reports providing insights into humidity levels and the performance of moisture protection measures.

Key Features:

Waterproof Design

- IP64-rated enclosure ensures resistance to water and dust.

Technical Specifications

- Temperature range: -30°C to 70°C

- Humidity: 5%–95% RH, accuracy ±3% RH

- Shock sensor: Measures up to 8G impacts

- Dimensions and weight: 103 x 61.3 x 30 mm, 140 g

4-in-1 Precision Sensors

Monitors:

- Temperature

- Humidity

- Door openings

- Shocks

Continuous Data Connectivity

- Real-time data transmission using 4G/5G LTE with fallback support for 2G networks.

Clear LCD Display

- Shows real-time data such as temperature, signal strength, battery level, and network connectivity, allowing quick activation checks.

Extended Battery Life

- Durable lithium-ion battery provides up to 120 days of continuous operation.

Comprehensive Reporting

- Retrieve full data via USB or download as PDF reports for detailed analysis.

Stages of the AbsorTest™ Process

1. Loading

- Step-by-step instructions: Includes completing forms with key details, such as container number and initial humidity levels.

- Photo documentation: Captures the loading process to ensure accuracy and compliance.

2. Transport

- Key parameter recording: Monitors temperature, humidity, light exposure, location, and G-force impacts.

- Real-time monitoring and alerts: Provides notifications when safety thresholds are exceeded.

3. Unloading

- Humidity measurement: Evaluates moisture levels upon arrival.

- Container assessment: Inspects the condition of the container and its contents.

AbsorTest™ Final Report

The collected data is compiled into a comprehensive report, which includes:

- Humidity and temperature analysis: Detailed insights into conditions during transport.

- Test results: Clear evaluation of desiccant effectiveness and transport conditions.

- Recommendations: Tailored advice for optimizing future shipments.

Validation Methods

-

Single Brand:

Tests performed using desiccants from a single brand in various configurations to determine their effectiveness. -

With/Without:

Comparison of containers with and without desiccants to evaluate their impact on humidity control. -

Multi-Brand:

Assessment of desiccants from different brands used within the same container to identify the most effective solution.

Advantages of AbsorTest™ and AbsorTrack™

- Comprehensive Cargo Control: Full monitoring of cargo conditions during transport.

- Sustainable Approach: Reduces losses caused by moisture, contributing to environmental sustainability.

- Cost Optimization: Minimizes transport damage, saving on expenses.

- Data Transparency: Real-time monitoring and detailed reporting provide clear insights into cargo conditions.

Contact Us

Don’t wait—trust our experts to tailor the AbsorTest™ system to your specific needs. With our support, your cargo will be effectively protected from moisture at every stage of transport.