Car lashing for auto transporters with a 3-point attachment system that meet VDI 2700 8.1 and 8.2 standards, guaranteeing the safe transportation of vehicles. The products provide excellent transmission and uniform distribution of standard tension force (STF). The webbing achieve the required performance level ETA ≥ 0.5. Maximum webbing elongation ≥4% ensures reliable load stability, reducing the need for re-tensioning during transport.

Properties:

- Performance: ETA ≥ 0.5

- Label with certificate number and inspector's label on the controller

- Meets the requirements of EN 12195-2

- According to VDI 2700 8.1 and 8.2, the webbing must not come into contact with the tire when securing the vehicle . Therefore, rubber or rubber-material protection must be used!

What do they mean for vehicle transport?

In September 2024, the new guidelines of VDI Standard 2700, Parts 8.1 and 8.2, which regulate how to secure vehicles on autotransporters, took effect. The changes are a step forward in the safety of transporting light and heavy vehicles, but also a challenge for transport companies operating in Germany and other European countries.

What is the VDI 2700 standard?

The VDI 2700 standard, developed by the Association of German Engineers (VDI), sets safety standards for road transportation. Its goal is to ensure the stability of transported loads through appropriate lashing techniques.

Parts 8.1 and 8.2 introduce specific guidelines for transportation:

8.1: light commercial vehicles and passenger cars weighing up to 4.5 tons.

8.2: medium and heavy commercial vehicles up to 20 tons.

.

The most important changes introduced by the new guidelines:

Banning webbing contact with tires

One of the most important changes is the complete ban on direct contact between webbing and vehicle tires.

Benefits:

-

- Tire protection: Controller do not cause abrasion or rubber deformation.

- Stability: Better holding of the vehicle on the auto transporter.

- Innovative solutions: Special pads, wedges and guards have been introduced.

New requirements for the lashing systems!

Webbing must meet stringent strength standards and have clear markings and certifications. In practice, this means that the webbing:

- They must pass dynamic tests (sudden braking, changes of direction).

- They should have increased resistance to mechanical loads and weather conditions.

- They must be regularly serviced and inspected for wear.

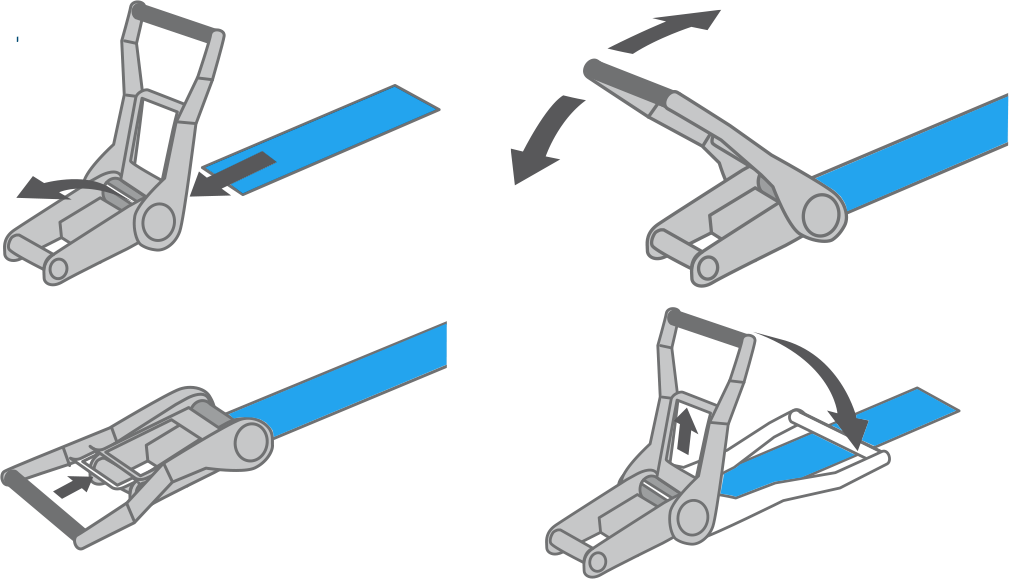

Vehicle mounting diagrams

The VDI 2700 standard introduces five updated security schemes that take into account the specifics of different vehicles:

- Personal: Point attachment within the suspension.

- Delivery vehicles: Techniques tailored to a higher center of gravity.

- Heavy vehicles: Use of additional beams and wedges.

- Hybrids: Combinations for unusual vehicles.

- Electric: Methods to protect sensitive components such as batteries.

Impact of VDI 2700 standards on the transportation industry

Adjustment costs

- Purchasing certified webbing, wedges and additional components can generate significant costs.

- Regular testing and servicing require money.

New procedures and training

- Drivers and crew must receive specialized training on new techniques for securing vehicles.

- Need to implement new procedures for loading and securing vehicles.

Risk of penalties

- Non-compliance during inspections in Germany can result in hefty fines and the detention of transport.

Why should standards be followed?

Despite the challenges, the implementation of the new regulations is bringing tangible benefits:

- Greater safety on the roads: Reducing accidents caused by load shifting.

- Vehicle protection: Absence of damage during transportation increases customer satisfaction.

- Reputation building: Compliance with standards demonstrates a company's professionalism.

- Avoiding legal problems: Certified equipment minimizes the risk of financial penalties.

The new VDI 2700 8.1 and 8.2 standards set a new standard for safety in vehicle transportation. Although their implementation entails costs and changes to daily operations, compliance is an investment in safety and professionalism.

If your company needs support in complying with the new requirements, we invite you to contact our team. We offer certified car lashing, chocks and other components that comply with VDI 2700 standards.

Forankra modern car lashings - safety and reliability in practice!

Transportation and logistics are industries where reliability and safety are of paramount importance. Any cargo being transported - from cars to delicate equipment - needs to be properly secured to reach its destination in perfect condition. That's why at Forankra we rely on the highest quality for our products, such as car lashing.

Durability of materials - what distinguishes our webbing?

Our lashing systems are manufactured from high-quality synthetic materials that are resistant to mechanical damage, moisture and changing weather conditions. As a result, they perform well both in the harsh conditions of road transport and in warehouses, where long-term reliability is required.

An additional advantage is the use of hardware and components, which ensure the stability of the tension, even under heavy use. Every detail of our products is designed with durability and safety in mind.

Versatility of applications

Forankra products are used in many industries:

- Road transport: Securing vehicles, machinery and construction materials.

- Heavy industry: Securing structural components and machinery.

- Agriculture: Transporting agricultural equipment or crops.

Customers value our products for their versatility, as they are easily adaptable to a variety of needs.

Standards and certificates - a guarantee of safety

Each Forankra webbing complies with VDI 2700 and other international standards. This ensures that our customers are using products that meet the highest safety requirements.

How to choose the right lashing system? Forankra guide for transporters:

Choosing lashing system can be difficult, especially when the market offers many solutions. As experts in cargo security, we've created a practical guide to help you make the best decision.

What to follow when choosing webbing?

- Durability: Determine what load the webbing will have to withstand. Our products are available in different load ratings to meet a variety of requirements.

- Length: A well-chosen length of webbing allows them to be used comfortably and minimizes the risk of cargo damage.

- Safety standards: Make sure your product has certifications, such as VDI 2700, to guarantee its quality.

The most common mistakes in using webbing

Even the best webbing can fail if not used properly. Here are some common mistakes:

- Improper attachment of webbing to the load, which can lead to shifting of the load.

- Using damaged or worn out webbing.

- Inadequate webbing tension, which increases the risk of an accident.

To avoid these problems, we recommend regular training and equipment maintenance.

Solutions for different types of cargo

Our range includes webbing tailored to various applications:

- Webbing for transporting vehicles: Equipped with special hooks so as not to damage the paint.

- Webbing for delicate materials: With soft covers to protect against abrasions.

- Heavy-duty webbing: Ideal for transporting heavy machinery.