Caking - Causes and Prevention Methods

Caking is an undesirable phenomenon that involves the formation of clumped masses of fine powder particles, such as cosmetics, food powders and pharmaceuticals. It manifests itself when powder particles begin to agglomerate, forming a mass that is difficult to disperse, making both application and storage of the product difficult.

Causes of Caking :

-

Moisture

Moisture is the main cause of clumping. Powders in contact with moisture, whether due to weathering or improper storage, can clump together to form agglomerates. Steam or liquid water also contributes to this process. -

Particle size and shape

Fine powders with smaller particles are more prone to clumping because the larger particle surface area promotes moisture absorption. In addition, particles with irregular shapes interlock more easily, which increases the tendency to caking. -

Hygroscopicity

Some powders, being hygroscopic in nature, tend to attract moisture from the environment. The absorption of moisture by these powders can lead to caking. -

Composition and formula

Powder ingredients, such as binders, fillers or additives, can exacerbate the tendency to caking. Inconsistent mixing of ingredients during production can also lead to particle agglomeration problems. -

Packaging and storage

Improper packaging and storage under unsuitable conditions, such as high humidity or wide temperature fluctuations, can cause powders to absorb moisture and lead to clumping.

Products Prone to Caking:

- Food Powders – spices, flour, cocoa, powdered drinks

- Pharmaceutical Powders – active ingredients, dietary supplements

- Cosmetics – powders, eyeshadows, blushes

- Chemical Powders – dyes, pigments, chemical additives

Methods to Prevent Caking:

-

Anti-Caking Agents

Special additives, such as silica or magnesium stearate, are used to prevent caking by controlling excess moisture and improving the flowability of powders. -

Particle Engineering

Techniques like spray drying or granulation modify the properties of powder particles, reducing their tendency to cake. -

Packaging and Storage

Using moisture-resistant packaging, as well as adding desiccants to containers, can effectively prevent powders from absorbing moisture and extend their shelf life. -

Regular Quality Inspections

Rigorous quality control during production enables early detection of caking tendencies and allows for quick resolution of potential issues.

Container Desiccants – An Effective Solution to Prevent Caking:

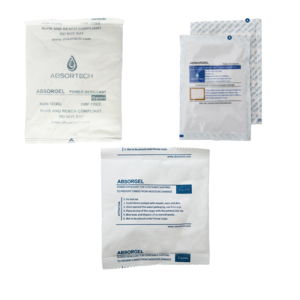

Container desiccants are specially designed accessories that control moisture levels in transport containers, providing protection against caking. Available in various forms such as bags, strips, or sachets, desiccants absorb moisture and reduce the relative humidity inside the container, effectively preventing the formation of caking.

Desiccants are not only effective but also economical and easy to use. Their proven track record in the transportation of powders demonstrates that they are a reliable tool in combating moisture issues. By integrating appropriate moisture protection measures and proper packaging, desiccants efficiently prevent caking and help maintain the quality of products.

Caking of powders poses a significant challenge in many industries. However, by implementing proper preventive measures such as anti-caking agents, particle engineering, appropriate packaging, and container desiccants, the risk can be effectively minimized, ensuring long-lasting product quality. A proactive approach to moisture control minimizes losses, increases customer satisfaction, and protects product integrity.