What is Container Rain?

Container transport is an economical and safe way to ship most types of cargo. However, sealing goods inside a steel container comes with the risk of container rain, which can damage nearly any kind of load.

Two main factors are necessary for this phenomenon to occur:

- Temperature fluctuations during transport

- Excess moisture

Every container contains moisture from the moment it is loaded, and its structure is not entirely airtight. Temperature fluctuations are difficult to eliminate and may involve high costs. However, reducing excess moisture is achievable by proper sealing and the use of desiccants, which remove moisture from the air and prevent condensation.

How Does Container Rain Form?

Warm air can hold more moisture than cold air. When the temperature drops, relative humidity increases, and upon reaching the dew point, moisture begins to condense. This process is especially noticeable when air comes into contact with cold surfaces of the container, such as the ceiling or walls, where water condenses and drips onto the cargo. Even a small temperature drop, e.g., by 5°C, can trigger condensation, leading to container rain.

Is a Container Airtight?

Before loading, it is essential to ensure the container is in good technical condition, especially the doors and ventilation openings. In a well-maintained container, the exchange of air and moisture is limited, reducing the risk of moisture entering.

If you are transporting dry cargo, it is advisable to seal the ventilation openings with tape to further minimize the risk of condensation.

Container Breathing

During container transport, especially over long distances, internal temperatures fluctuate with the day-night cycle. This causes the air to expand and contract, drawing moist air from outside. This phenomenon, known as container breathing, increases the amount of moisture inside the container, further intensifying the risk of condensation.

Is a Container Dry?

Moisture can come not only from the air but also from the container itself, especially if it was washed before loading. It is important to check the container floor, as well as wooden pallets and dunnage, which can further increase the moisture level.

Cargo, especially organic or hygroscopic materials, may also contain water. Using a handheld moisture meter to assess the moisture level in materials before loading is highly recommended.

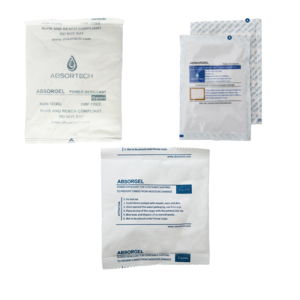

During the day, as the temperature inside the container rises, moisture from the floor, pallets, or cargo evaporates into the air, increasing the absolute humidity and raising the risk of condensation. Therefore, it is crucial to use desiccants, which effectively reduce the moisture level in the enclosed space.

By properly preparing containers and utilizing modern technologies like desiccants, the risk of moisture-related damage can be significantly minimized, protecting the cargo from the harmful effects of container rain.